MIRACLE Shank Adapter

The specification and hardness of shank adapter have a great influence on the rock drilling speed and the life of the rock drill. The hardness of the shank adaptors for drill should be appropriate, the service life is short if the rock drill shank is too soft, the piston is vulnerable to damage if the drill shank adapter is too hard. MIRCALE shank adapter factory has accurate specifications, smooth surface, suitable hardness, the cross-section is perpendicular to the axis, and closely coincides with rock drill sleeve.

MIRCALE offers male and female threaded shank adapter, also called striking bar or shank rod, such as T38/T45/T51 shank adaptor, etc. Our shank adapters are suitable for various brands of rock drills, such as Atlas Copco, Sandvik, Furukawa, Montabert, Ingersoll-Rand, Tamrock, Boart Longyear,Soonsan,Everdigm,etc., and the rock drill shank adapter (drill shank adaptor) also can be designed according to customer needs.

Rock drill with Shank Adapter: ↓

Brands covered

MIRCALE Shank Adapters cover world main drill rigs brands and drifter as follows :

– Atlas Copco (COP1238, COP1840, COP1638, COP1838, COP2150, COP2550, COP2160, COP2560 etc.)

– Furukawa (HD609, HD709, HD612, HD712 etc.)

– Sandvik (HL500, HL600, HL700, HL800, HL1000, HL1500, HLX5 etc.)

– Ingersoll Rand (YH65, YH70, YH80, YH60, YH135 etc.)

– Montabert (HC109, HC158, HC120, HC150, HC80 etc.)

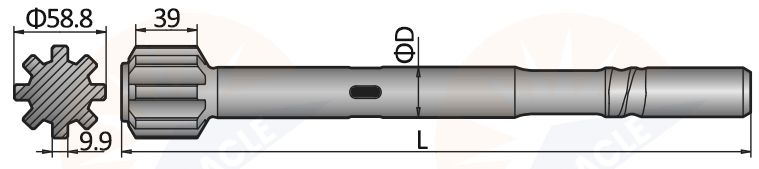

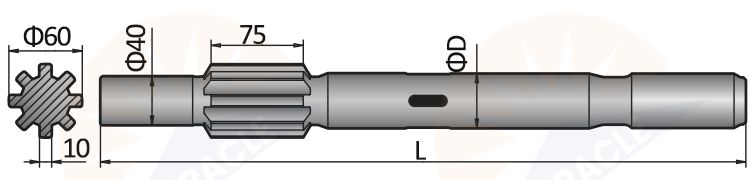

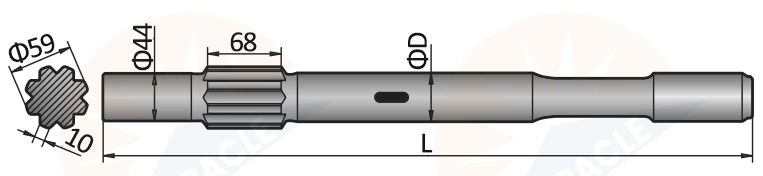

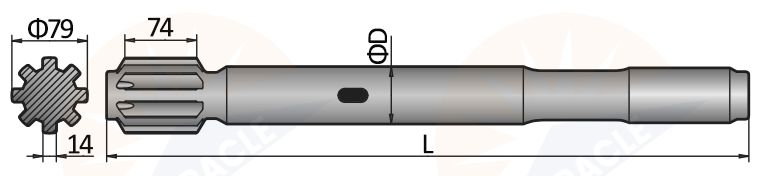

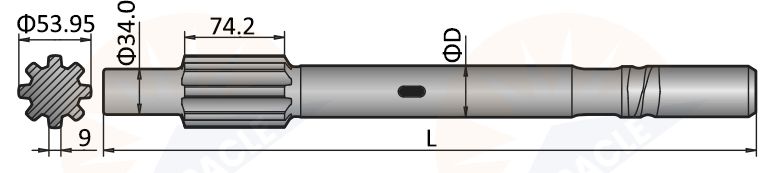

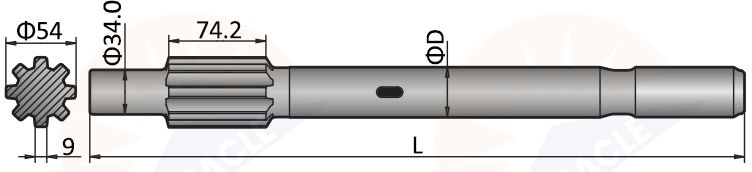

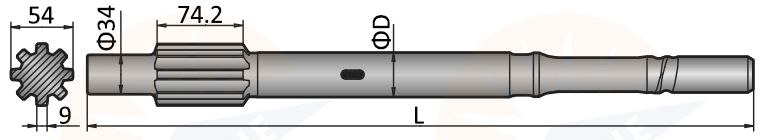

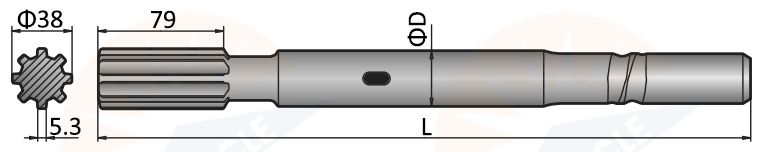

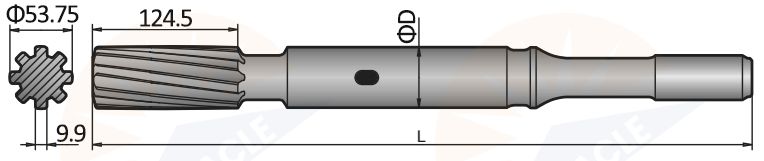

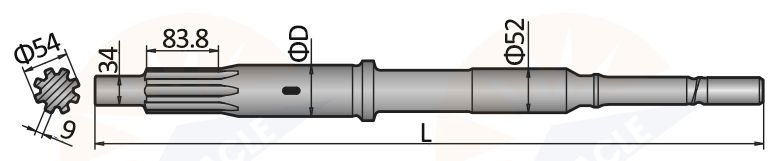

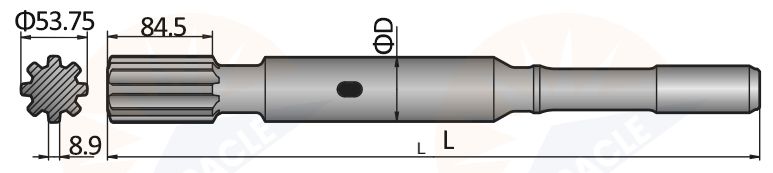

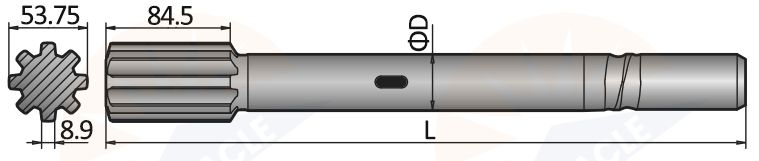

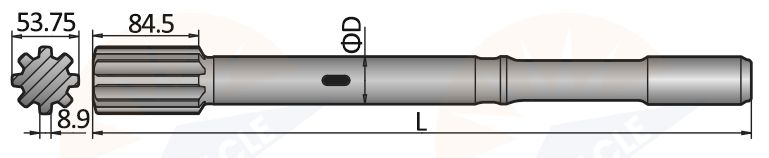

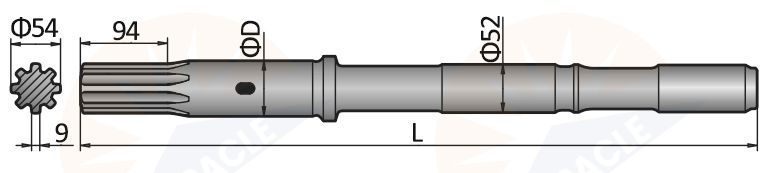

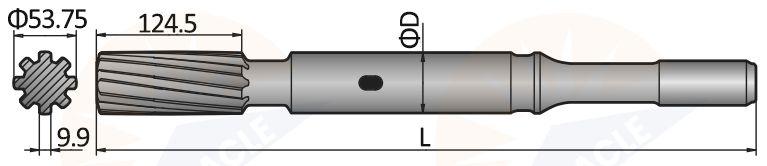

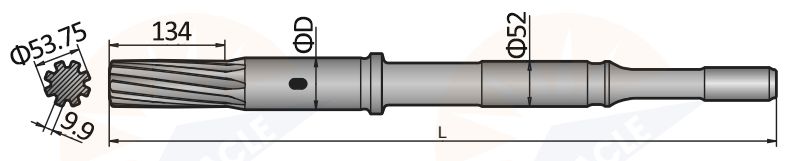

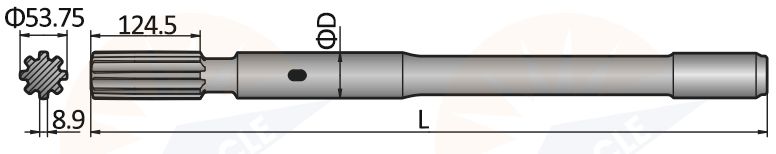

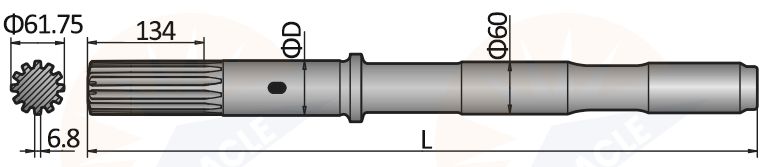

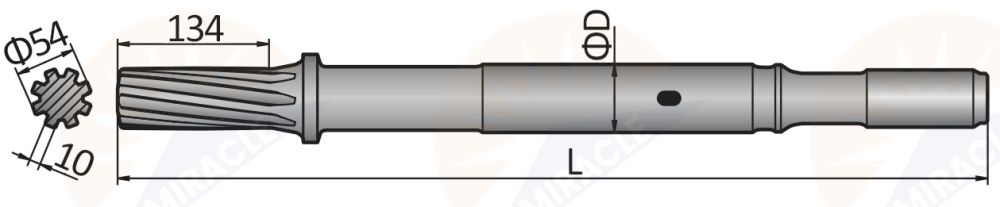

Product Specification

Product | Top Hammer Rock Drilling Tool - Shank Adapter |

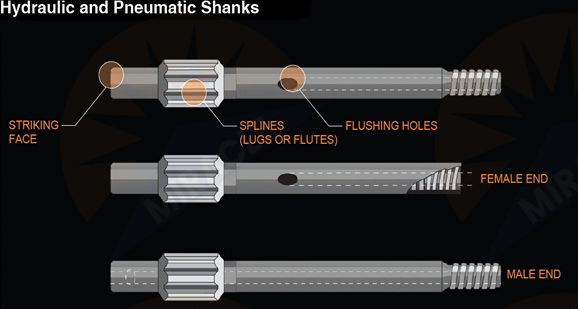

Other Names | Top hammer shank adaptor, Drill shank adapter, Striking bar, Hydraulic shanks, Shank bar, strike bar |

Material | Structural Alloy Steel |

Application | Tunnelling , Mining , Quarrying, Blasting and Infrastructure Construction Facedrilling and Bolting, Bench Drilling, Production drilling, Long hole drilling, Drifting |

Applicable rock drill | Atlas Copco (Epiroc), Sand vik (Tamrock), Furukawa, Ingersoll-Rand, Montabert, Boart LongYear, etc. |

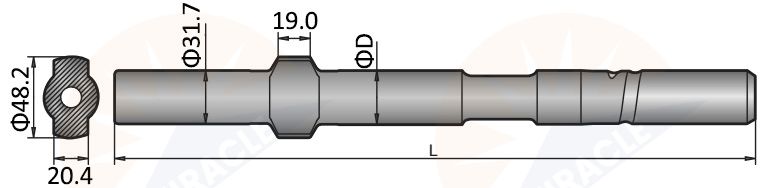

Shank Type | Male threaded shank adapter, Female threaded shank adapter |

Thread Type | R25, R28, R32, R35, R38, T38, T45, T51, GT60, ST58, ST68, EL60, EL68, etc. |

Diameter | 32mm~90mm |

Length | 273mm~885mm |

Custom Design | Acceptable |

Product Advantages

• High-quality steel

MIRCALE shank adapters use high-quality alloy structural steel as the raw material, undergoes overall carburizing treatment, and adopt special CNC machine tool processing equipment and processing flow to ensure the processing quality of splines, water holes and other details, which can meet the requirements of drilling harder rock layers and have a longer service life.

• Advanced manufacturing technology

MIRCALE shank adapters adopt advanced thread manufacturing technology and advanced surface treatment technology, and are manufactured according to precise tolerances. They have the characteristics of tight connection, good energy transmission effect, strong wear resistance, and easy disassembly. Our shank adapters are uniformly heat-treated and scientifically straightened with precision instruments to ensure straightness and anti-irritability.

• Strict quality control

All the top hammer shank adapters produced by MIRCALE shank adapter factory are strictly controlled to ensure that they have satisfactory high quality.

Shank Adapter For Rock Drills (Drifters)

We manufacture high-quality shank adapters for most brands of rock drills (Drifters).

Rock drill brand | Rock Drills (Drifters) Models |

Atlas Copco Epiroc | COP1028, COP1028HB, COP1032HL, COP1036, COP1038, COP1132, COP1238, COP1238DSA/SDA, COP1240, COP131EB, COP1432, COP1440, COP1532, COP1550, COP1550EX, COP1638, COP1640, COP1838, COP1838EX/MUX/HUX/AW, COP1840, COP2150, COP2160, COP2160EX, COP2238, COP2540, COP2540EX, COP2550, COP2550UX, COP2560, COP2560EX, COP3038, COP3060, COP4038, COP4050EX/MUX, COP4050ME, COP628, COPCS16, COPCS19, COPMD20, COPRR11, COPRR14, COPSC16, COPSC14, COPSC19, COPSC19X, COPSC25-HE, COPSC25-HF, BBC54, BBE57, BBC120, RD14S/18S/22S, RD14U/18U/22U, RD8 Yamamoto KOP1540YH-70A, Yamamoto KOP175 |

Sandvik Tamrock | HL1000, HL1000-60, HL1000PE-65, HL1000S, HL1010, HL1010-60, HL1010 PE-65/S-52, HL1060T/PE-65, HL1500, HL1500-60, HL1500PE-65, HL1500SPE-90, HL1500T/PE-65, HL1500T-52, HL1500-T60, HL1560ST PE-90, HL1560T/PE-65, HL1560T-65, HL300S, HL500, HL500-45, HL500F, HL500S, HL500S-38, HL500SUPER, HL510-45, HL510B, HL510F, HL510LH, HL510S-38, HL510S-45, HL538, HL538L, HL550S, HL560S, HL560SUPER, HL600, HL600-45, HL600-52, HL600S, HL600S-45, HL645, HL650-45, HL650-52, HL700, HL700-45, HL700-52, HL710-45, HL71052, HL710PE52, HL710S, HL710SPE-52, HL800, HL800T-45, HL800T52, HL800T-52, HL850, HL850S, HFX5, HLR438L, HLR438LS, HLR438T, HLR438TS, HLX1, HLX3, HLX5, HLX5T, L400, L500, L550S, RD1635 CF, RD314, RD520, RD525 PE, RD926L, 438 LS/TS |

Ingersoll-Rand | Ingersoll-Rand 350, EVL130, Hydrastar 200, LM500, VL120, VL140, YD90M, YH65, YH65RP, YH70, YH75RP, YH80A, YH80RP, YH95, YH95RP, YH110V, YH135V, URD475, URD550 |

Montabert | H50, H60, H70, HC20, HC25, HC40, HC50, HC80, HC80RP, HC80, HC80R, HC90, HC95, HC95RP, HC105, HC108R, HC109, HC109RP, HC110, HC120, HC120RP, HC150RP, HC155RP, HC158RP, HC160, HC170, HC200, HC200A, TA 35-LC 50, |

Boart LongYear | HD65, HD125, HD150, HE65, HE125, HE150, HE155, SECO HD155 |

Furukawa | PD200, PD200R, HD90, HD190, HD210, HD300, HD500, HD609, HD609RP, HD612, HD612RP, HD615, HD709, HD712, HD712 RP/EX, HD715, HD715RP |

Gardner Denver | Gardner Denver 93, HPR1H, HPR2, HPR5123, HPR5123 (REEDRILL), HPR-C(INCO) / HPRH-D, HPR-C, HPRH-D, PR123, IR VL120, VL140 |

Other Brands | Böhler HM751 Cannon CH-32, CH-38 Joy JH2, 400RR, VCR260 Krupp HB51, HB100, HB101 Permon HVKS 125-1 Secoma Hydrastar 200, 300, X2 SIG 100, 150 Everdigm ED100, Soonsan ED100, John Henry HB101/HB102, HRP51 |

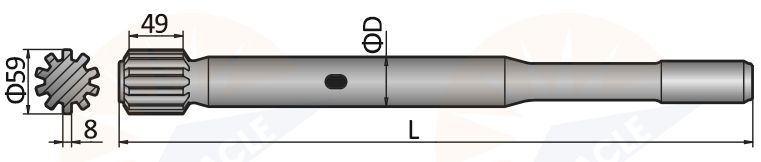

Specification Of Sandvik

HLX 5, HLX 5T

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | R38 | 500 | 45 | 5.2 | R38*10D45-500 | 7804-7585-01 / 90516173 |

DT | T38 | 500 | 45 | 5.1 | T38*10D45-500 | 7304-7585-01 / 90516198 |

DT | T45 | 500 | 45 | 5.5 | T45*10D45-500 | 90003672 |

BE | T38 | 575 | 45 | 5.7 | T38*10D45-575 | 7304-7586-01 / 90516199 |

BE | T45 | 575 | 45 | 5.9 | T45*10D45-575 | 7305-7586-01 / 90516144 |

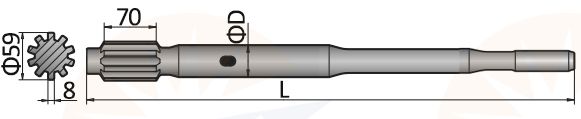

RD520, RD525

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | T38 | 525 | 45 | 5.7 | T38*10D45-525 | 7304-7669-01 |

DT | T38 | 600 | 45 | 6.6 | T38*10D45-600 | 7304-7666-01 |

HL 500, HL 510

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | R32 | 550 | 45 | 5.4 | R32*8D45-550 | 7803-7557-01 |

BE | T38 | 550 | 45 | 5.6 | T38*8D45-550 | 7304-7557-01 |

BE | T45 | 550 | 45 | 5.9 | T45*8D45-550 | 7305-7557-01 / 90516207 |

HL 300

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | R32 | 400 | 32 | 2.6 | R32*8D32-400 | 7803-7549-01/ 90516166 |

HL 600, HL 600S

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT/PD | T38 | 525 | 45 | 5.6 | T38*8D45-525 | 7304-7537-01 / 90516191 |

| DT/PD | T45 | 525 | 45 | 5.8 | T45*8D45-525 | 7305-7537-01 / 90516210 |

HL 645,HL 645S

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T45 | 600 | 45 | 6.5 | T45*8D45-600 | 7305-7541-02 / 90502270 |

HL 1000, HL 1000S

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

PD | T51 | 590 | 52 | 9.3 | T51*8D52-590 | 7306-6008-01 / 90516036 |

BE | T45 | 670 | 52 | 10.0 | T45*8D52-670 | 7305-6010-01 / 90516027 |

BE | T51 | 670 | 52 | 10.0 | T51*8D52-670 | 7306-6010-02 / 90516037 |

HL1000 PE-65, HL 1500, HL 1500 PE-65, HL 1560 T-65

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T51 | 760 | 65 | 16.3 | T51*8D65-760 | 7306-6025-02 / 90003702 |

Specification Of Atlas Copco

Atlas Copco COP 125, COP130, COP131

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT/BE/PD | T38 | 380 | 38 | 3.0 | T38*3D38-380 | 7304-4500-60 / 90515979 |

DT/BE/PD | T45 | 380 | 38 | 3.0 | T45*3D38-380 | 90515994 |

Atlas Copco COP 1032 HD

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT/BO | R32 | 340 | 45 | 3.4 | R32F*8D45-340 | 7803-3588-01 / 90515883 |

DT/BO | R38 | 340 | 55 | 4.1 | R38F*8D55-340 | 7804-3575-01 / 90516169 |

Atlas Copco COP 1032 LE

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | R32 | 550 | 45 | 4.8 | R32*8D45-550 | 7803-3576-01 / 90515884 |

Atlas Copco COP 1036, COP1038, COP1238

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | R32 | 485 | 38 | 4.0 | R32*8D38-485 | 7803-3590-03 / 90515890 |

DT | R38 | 485 | 38 | 4.2 | R38*8D38-485 | 7804-3590-03 / 90515961 |

DT | T38 | 485 | 38 | 4.2 | T38*8D38-485 | 7304-3590-03 / 90515983 |

| BE | R32 | 500 | 38 | 4.0 | R32*8D38-500 | 7803-3591-01 / 90515887 |

| BE | T38 | 500 | 38 | 4.4 | T38*8D38-500 | 7304-3591-01 / 90515980 |

| BE | T45 | 500 | 45 | 5.0 | T45*8D45-500 | 7305-3591-01 / 90515995 |

| BE/PD | R32 | 575 | 38 | 4.6 | R32*8D38-575 | 7803-3593-01 / 90515888 |

| BE/PD | R38 | 575 | 38 | 4.7 | R38*8D38-575 | 90515899 |

| BE/PD | T38 | 575 | 38 | 4.9 | T38*8D38-575 | 7304-3593-01 / 90515981 |

| BE/PD | T45 | 575 | 45 | 5.8 | T45*8D45-575 | 7305-3593-01 / 90515996 |

Atlas Copco COP 1132

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT/BO | R32 | 410 | 35 | 2.5 | R32*8D35-410 | 7803-3581-02 / 90515862 |

PD | R32 | 500 | 35 | 3.0 | R32*8D35-500 | 7803-3583-02 / 90515864 |

Atlas Copco COP 1240

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | R32 | 565 | 52 | 6.4 | R32*8D52-565 | 90515834 |

BE | T38 | 565 | 52 | 6.6 | T38*8D52-565 | 90516125 |

Atlas Copco COP 1338EX

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE/PD | R32 | 780 | 60 | 10.1 | R32*8D60-780 | 90516273 |

Atlas Copco COP 1440, COP 1550, COP 1838

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T45 | 525 | 52 | 6.1 | T45*8D52-525 | 7305-3655-01 / 90516206 |

BE | T51 | 525 | 52 | 6.5 | T51*8D52-525 | 7306-3655-02 / 90516217 |

Atlas Copco COP 1440, COP 1550, COP 1638, COP 1838, COP 2238

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | R32 | 435 | 38 | 3.6 | R32*8D38-435 | 7803-3652-01 / 90516087 |

DT | R38 | 435 | 38 | 3.9 | R38*8D38-435 | 7804-3652-01 / 90516098 |

DT | T38 | 435 | 38 | 3.8 | T38*8D38-435 | 7304-3652-01 / 90516120 |

| BE | R32 | 525 | 38 | 4.2 | R32*8D38-525 | 7803-3656-02 / 90516088 |

| BE | R38 | 525 | 38 | 4.3 | R38*8D38-525 | 90516099 |

| BE | T38 | 525 | 38 | 4.3 | T38*8D38-525 | 7304-3656-01 / 90516121 |

Atlas Copco COP 1838EX

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 730 | 60 | 9.8 | T38*8D60-730 | 7304-3825-02 / 90516288 |

BE | T45 | 730 | 60 | 10.2 | T45*8D60-730 | 7305-3826-02 / 90516304 |

BE | T51 | 730 | 60 | 10.4 | T51*8D60-730 | / 90516316 |

Atlas Copco COP 1840

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T45 | 565 | 52 | 6.8 | T45*8D52-565 | 7305-3690-02 / 90516128 |

BE | T51 | 565 | 52 | 7.2 | T51*8D52-565 | 7306-3690-03 / 90516129 |

Atlas Copco COP 1840EX

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T45 | 770 | 60 | 10.8 | T45*8D60-770 | 90516305 |

BE | T51 | 770 | 60 | 10.9 | T51*8D60-770 | 90516317 |

Atlas Copco COP 2150, COP 2550

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T51 | 770 | 52 | 9.9 | T51*8D52-770 | 7306-3692-01 / 90516000 |

Atlas Copco COP 2160EX, COP 2560EX

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T51 | 770 | 63 | 13.3 | T51*12D63-770 | 7306-3699-01 / 90516048 |

Atlas Copco COP 2550UX

App. | Thread | Length [mm] | Diameter [mm] | Weight[kg] | Model No. | Similar Part No. |

PD | T45 | 770 | 60 | 12.9 | T45*8D60-770 | 90516030 |

PD | T51 | 770 | 60 | 13.1 | T51*8D60-770 | 90516041 |

Atlas Copco BBC 43, BBC 44, BBC 45, BBC 100

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | R32 | 380 | 32 | 2.1 | R32*2D32-380 | 7803-3100-30 / 90515858 |

Atlas Copco BBC 51, BBC 52, BBC 54, BBC 120

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | R32 | 380 | 38 | 2.6 | R32*2D38-380 | 7803-4200-30 / 90516156 |

DT | R38 | 390 | 38 | 3.1 | R38*2D38-390 | 90516168 |

DT | T38 | 390 | 38 | 3.1 | T38*2D38-390 | 7304-4200-30 / 90516180 |

Atlas Copco BBE 57

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | R38 | 447 | 45 | 5.0 | R38*6D45-447 | 90516276 |

BE | T38 | 540 | 45 | 5.3 | T38*6D45-540 | 90516287 |

BE | T45 | 550 | 45 | 5.9 | T45*6D45-550 | 90516303 |

Specification Of Furukawa

Furukawa HD300

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | T38 | 655 | 45 | 6.0 | T38*6D45-655 | 90516388 |

DT | T45 | 655 | 45 | 6.7 | T45*6D45-655 | 90502638 |

Furukawa HD609

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 690 | 45 | 6.5 | T38*8D45-690 | 7304-4780-01 / 90516197 |

BE | T45 | 620 | 45 | 6.2 | T45*8D45-620 | 7305-4791-01 / 90510276 |

BE | T45 | 690 | 45 | 6.8 | T45*8D45-690 |

Furukawa HD612

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T45 | 710 | 51 | 8.7 | T45*8D51-710 | 7305-7414-01 |

BE | T51 | 710 | 51 | 9.7 | T51*8D51-710 |

Furukawa HD709

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 590 | 45 | 6.0 | T38*8D45-590 | |

BE | T45 | 590 | 45 | 6.4 | T45*8D45-590 | |

BE | T38 | 620 | 45 | 6.1 | T38*8D45-620 | 7304-7426-01 / 0000000 |

BE | T45 | 620 | 45 | 6.5 | T45*8D45-620 |

Furukawa HD712

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T45 | 590 | 51 | 8.7 | T45*8D51-590 | |

BE | T45 | 790 | 51 | 10.5 | T45*8D51-790 | 7305-7417-01 |

BE | T51 | 790 | 51 | 10.7 | T51*8D51-790 |

Furukawa PD 200

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 380 | 44.5 | 4.2 | T38*4D44-380 | 7304-7543-60 |

DT | T38 | 485 | 44.5 | 4.8 | T38*4D44-485 | 90516024 |

Specification Of Montabert

Montabert HC 40, HC 50

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BO/DT | R32 | 370 | 38 | 3.0 | R32*8D38-370 | 90515895 |

BO/DT | R38 | 370 | 38 | 3.3 | R38*8D38-370 | 90515966 |

BO/DT | T38 | 370 | 38 | 3.2 | T38*8D38-370 | 90515989 |

BE | R32 | 445 | 38 | 3.5 | R32*8D38-445 | 7803-4725-01 / 90515894 |

BE | R38 | 445 | 38 | 4.0 | R38*8D38-445 | 90515965 |

BE | T38 | 445 | 38 | 4.8 | T38*8D38-445 | 7304-4725-01 / 90515988 |

Montabert HC 40, HC 50 (female)

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BO/DT | R32 | 270 | 45 | 2.8 | R32F*8D45-270 | 7803-4726-01 |

BO/DT | T38 | 320 | 55 | 4.1 | T38F*8D55-320 | 90516183 |

Montabert HC 95

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

PD/DT | T38 | 512 | 45 | 5.8 | T38*8D45-512 | |

PD/DT | T45 | 512 | 45 | 6.1 | T45*8D45-512 |

Montabert HC 109

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE/DT | R38 | 460 | 45 | 5.2 | R38*8D45-460 | |

BE/DT | T38 | 460 | 45 | 5.2 | T38*8D45-460 | |

BE/DT | T38 | 490 | 45 | 5.5 | T38*8D45-490 |

Montabert HC 80, HC 90, HC 105, HC 120

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

DT | R32 | 440 | 38 | 3.6 | R32*8D38-440 | 7803-4720-01 / 90515893 |

DT | R38 | 440 | 38 | 3.9 | R38*8D38-440 | 7804-4720-01 / 90515964 |

DT | T38 | 440 | 38 | 3.9 | T38*8D38-440 | 7304-4720-01 / 90515985 |

Montabert HC 80 RP, HC 105 RP, HC 107 RP, HC 108 RP, HC 109 RP

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 670 | 45 | 7.2 | T38*8D45-670 | 7304-7544-01 / 90516522 |

BE | T45 | 670 | 45 | 7.5 | T45*8D45-670 | 90516213 |

Montabert HC 110

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 420 | 45 | 4.8 | T38*8D45-420 |

Montabert HC 120 RP, HC 150 RP, HC 155 RP, HC 158 RP

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T45 | 670 | 51 | 8.8 | T45*8D51-670 | 90516212 |

BE | T51 | 670 | 51 | 8.9 | T51*8D51-670 | 7306-7528-02 / 90516218 |

Specification Of Ingersoll-Rand

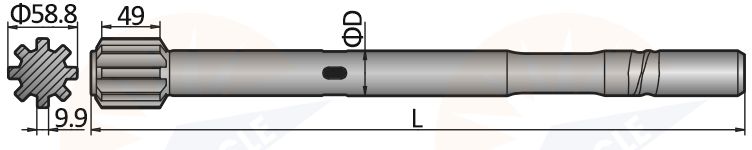

Ingersoll Rand YH 65,YH 70

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 500 | 45 | 5.2 | T38*6D45-500 | 90516283 |

BE | T45 | 500 | 45 | 5.5 | T45*6D45-500 | 7305-7525-19 / 90516299 |

Ingersoll Rand YH 65RP

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 700 | 45 | 7.8 | T38*6D45-700 | 90516285 |

BE | T45 | 700 | 45 | 7.9 | T45*6D45-700 | 7305-7546-19 / 90516301 |

Ingersoll Rand YH 80A

App. | Thread | Length [mm] | Diameter [mm] | Weight [kg] | Model No. | Similar Part No. |

BE | T38 | 500 | 51 | 5.5 | T38*6D51-500 | 90516284 |

BE | T45 | 500 | 51 | 5.7 | T45*6D51-500 | 7305-7559-19 / 90516300 |

BE | T51 | 500 | 51 | 6.4 | T51*6D51-500 | 90516313 |

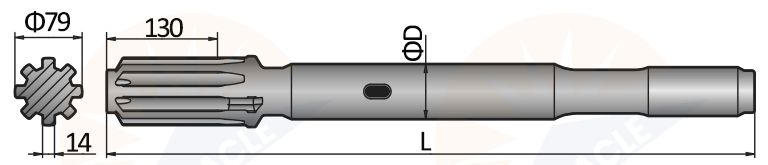

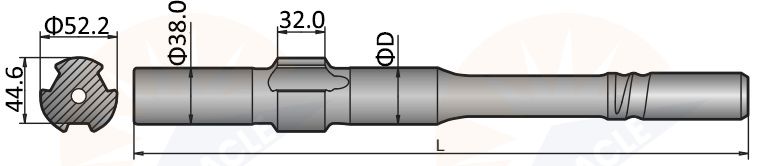

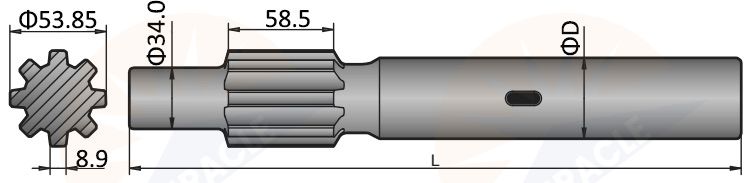

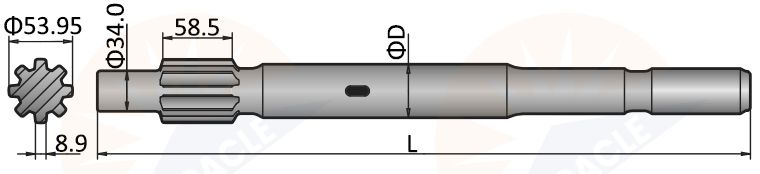

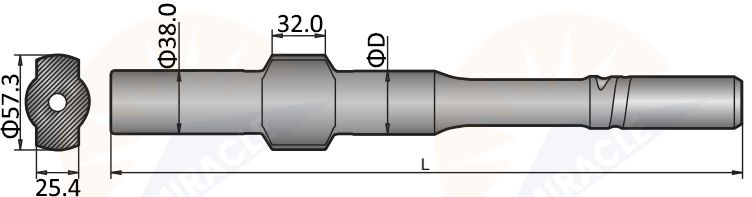

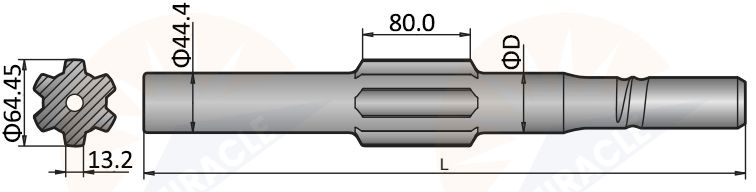

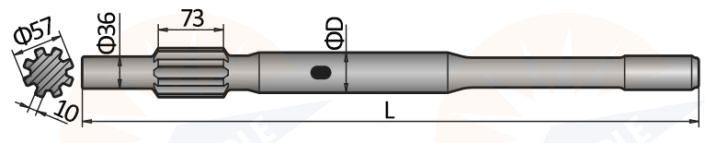

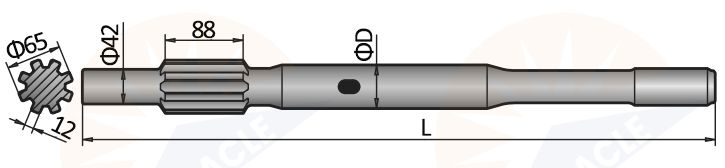

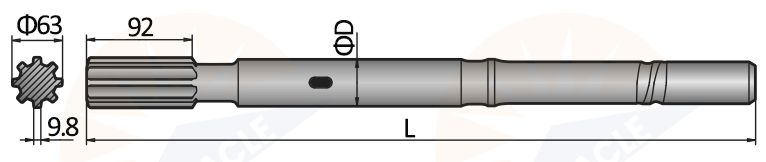

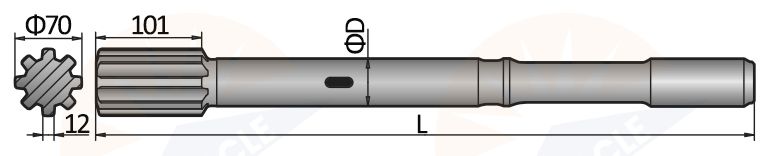

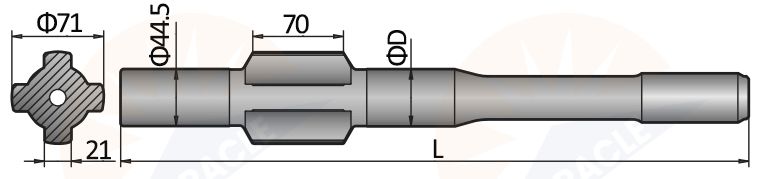

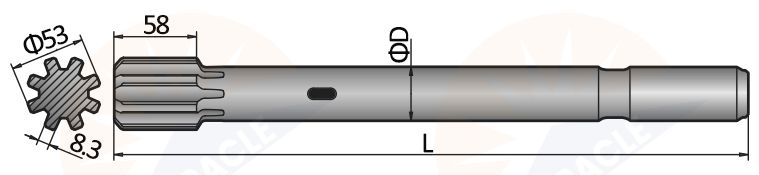

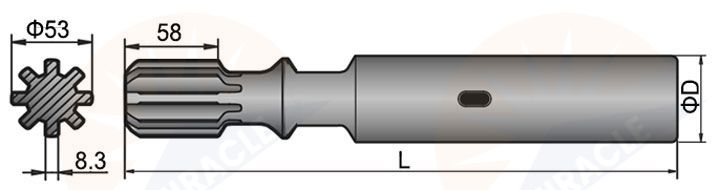

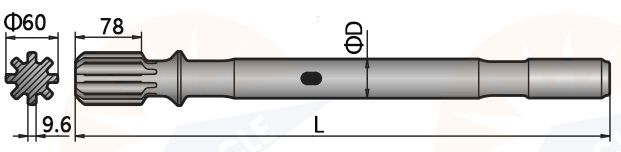

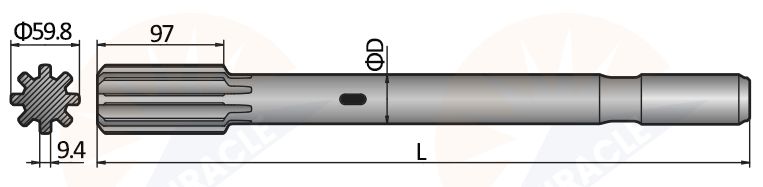

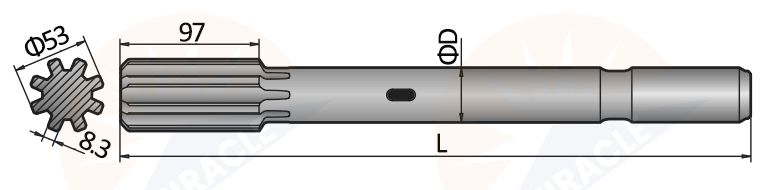

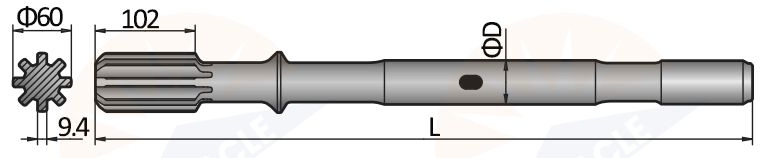

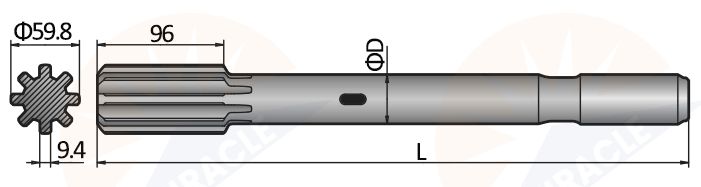

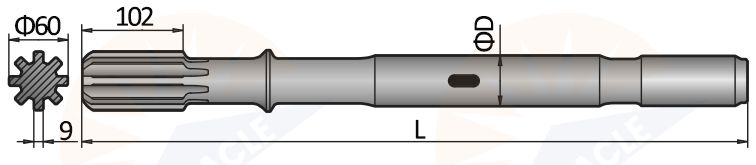

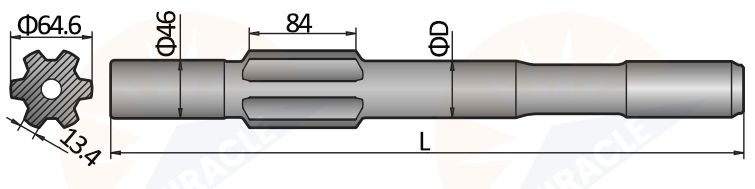

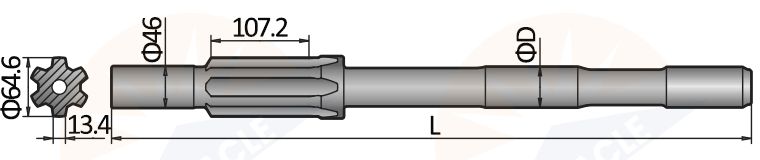

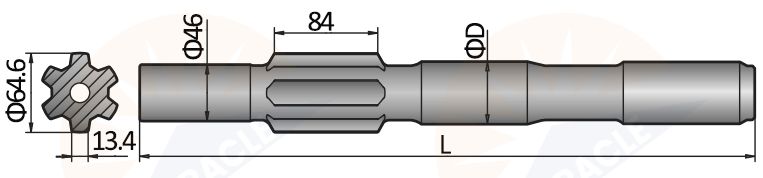

Two flushing options of shank adapters: internal or external

– Internal flushing uses a water tube that fits through the center of the drill and into an o-ring seal in the end of the shank, to transfer flushing into the drill string.

– External flushing, holes or a slot are required in the side of the shank adapter.These line up between seals inside the front head or water box of the rock drill, when the shank is installed. Flushing medium is supplied directly to this device and is introduced into the drill string through the shank.

– External flushing is considered superior to internal flushing, as greater volumes of flushing agent can be delivered with less risk of leakage and hammer damage from water.

The shanks for hydraulic drills and some pneumatic drills have external or front head flushing. Hydraulic shanks generally have at least 5 to 14-spline configuration, Pneumatic shanks tend to have internal or through flushing and can generally be identified by their lugs or 4-spline configuration.

Please contact our sales team for more specifications.

Our advantage:

1. Enterprise group combines manufacture and international trade;

2. Strict quality controll system with perfect equipment;

3. High technology enterprise with advanced production equipments;

4. Prompt delivery and all-around after-sales service;

FAQ

A: Are you trading company or manufacturer ?

Q: We are manufacturer.

A: Do you provide samples ?

Q: Yes, of course. We welcome sample order to test and check quality.

A: Can you accept small orders?

Q: We enjoy to cooperate with all clients whatever big or small order.

A: Could you accept OEM & ODM?

Q: Of course, as a manufacturer, OEM & ODM is available, our professional R&D center can help you on the project.

A: How long is your delivery time?

Q: Usually it's about 20 days,depends on your actual quantity.

Any question, pls feel free to contact . Thanks!