Symmetric Casing Systems

The Symmetric Casing Systems is a clever and simple concentric circle method that drills by covering the casing. Symmetric Casing Systems can drill holes at any angle (including horizontal direction) and the depth exceeds 100 meters.

Symmetric Casing Systems can be used in a wide range of applications where you need to drill in difficult ground conditions. The following are examples of the most common applications:

● Geothermal well drilling

● Water well drilling

● Pipe roofing

● Foundation work

● Anchoring

Symmetric casing systems drilling methods:

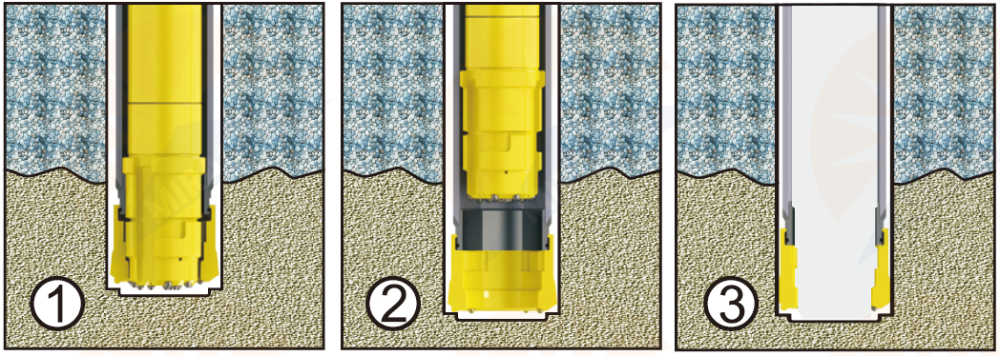

Retrievable Symmetric Drilling Tools with Casing Tube Step-by-Step:

① When the drilling starts, the central bit drives the ring bit down the hole, meanwhile the casing shoe and casing tube follow down together.

② When arriving at the bedrock, reversely rotate the tools and the central bit is pulled out from the hole.

③ During pouring the concretes through the casing tube, pull out the casing tube with the ring bit synchrony.

The retrievable casing is used when the casing is only needed during the drilling process, that is when it is used to keep the hole open during drilling and not used as support in the finished structure.

This is a cost-effective solution for piles and anchoring since the casing is retrieved from the hole and reused.

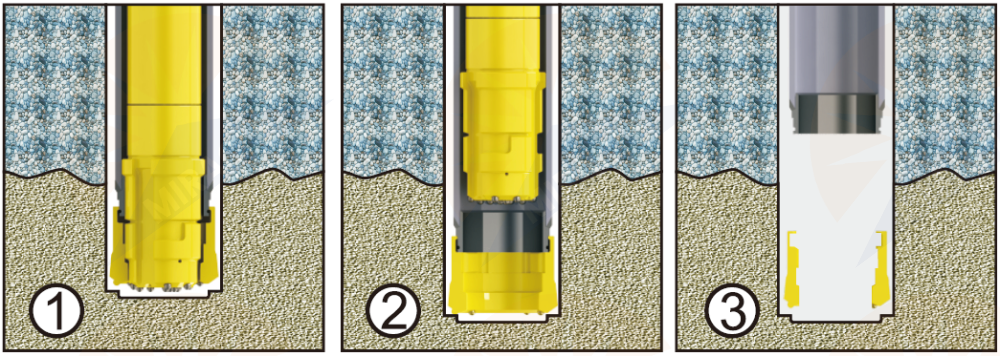

Permanent Symmetric Drilling Tools with Casing Tube Step-by-Step:

① When the drilling starts, the central bit drives the ring bit down the hole, meanwhile the casing shoe and casing tube follow down together.

② When arriving at the bedrock, reversely rotate the tools and the central bit is pulled out while leaving the ring bit in the hole bottom.

③ Pouring the concretes into the casing tube or moving to the next filed work process.

There are different applications where the permanent casing is the preferred choice, the most common are water wells, geothermal wells, foundation works, and pipe roofing.

In water and thermal wells, the casing is used as a sacrificial element to just keep the hole open. In foundation works, a permanent casing can work as a bearing structure of the pile, as a sacrificial element to protect the pile against corrosion, or just to keep the hole open.

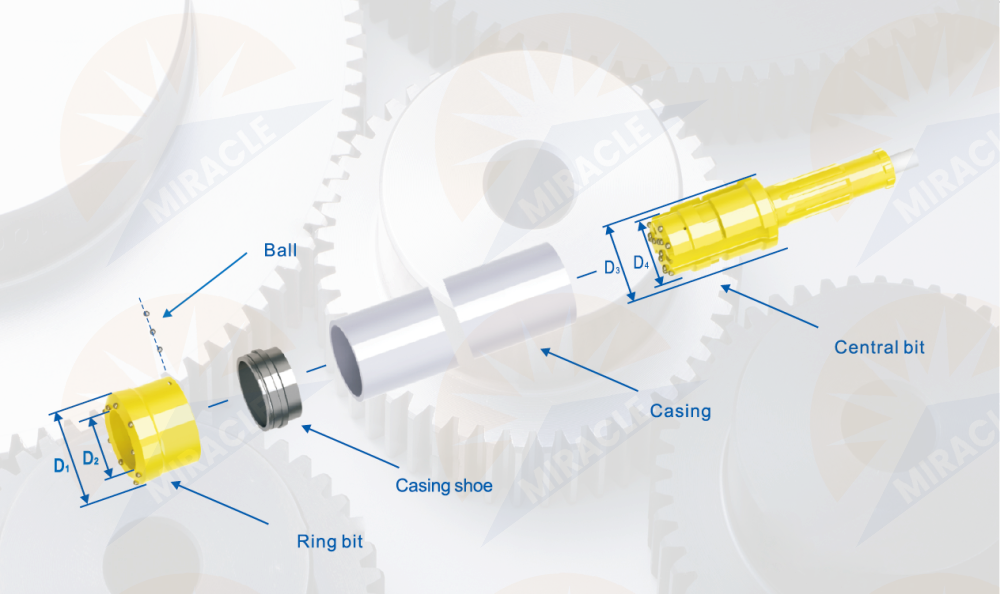

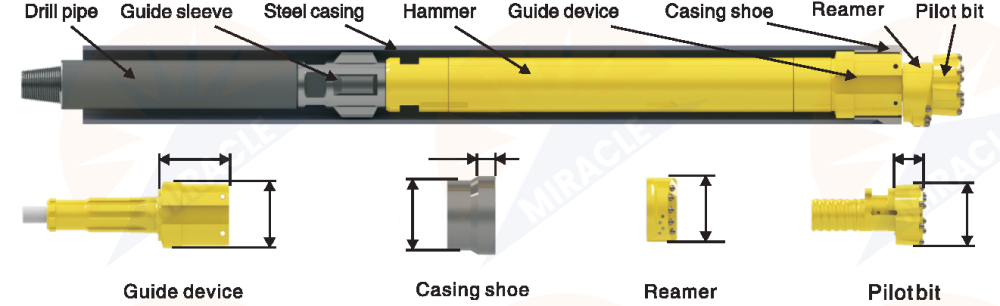

As an efficient drill bit system, the system is composed of the following components:

Central bit (with a huge drainage port and surface powder discharge groove inside)

Ring bit (with a bayonet inside, which can be connected to the guide drill bit)

Casing shoe (used to connect the drill bit and the casing)

Different guide drill bit tail handles can be connected to common down-the-hole impactors or connected to the top hammer drill rod thread.

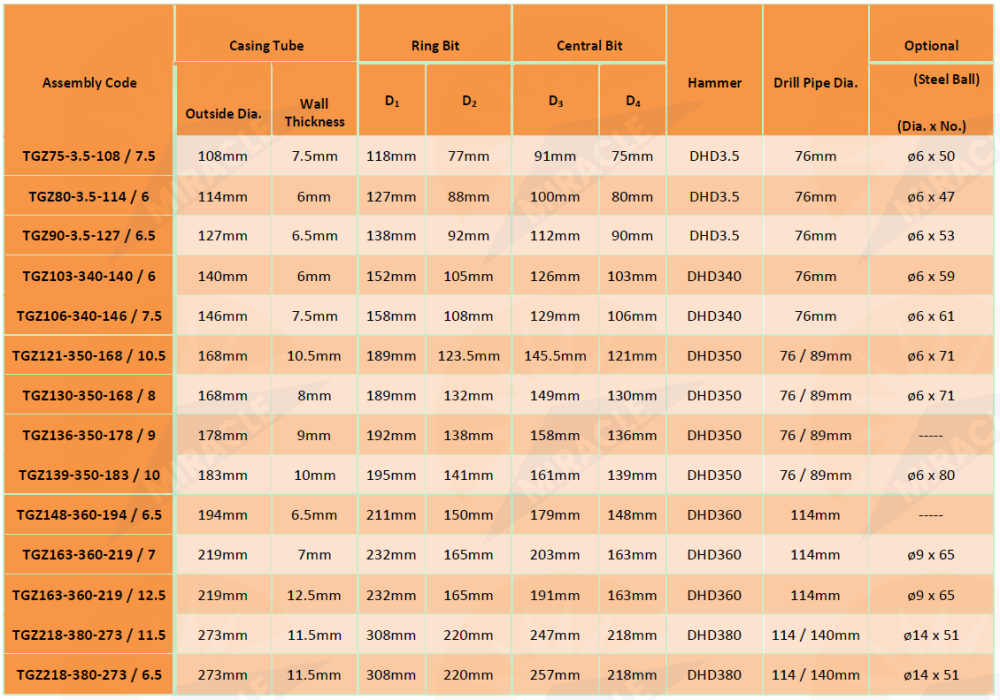

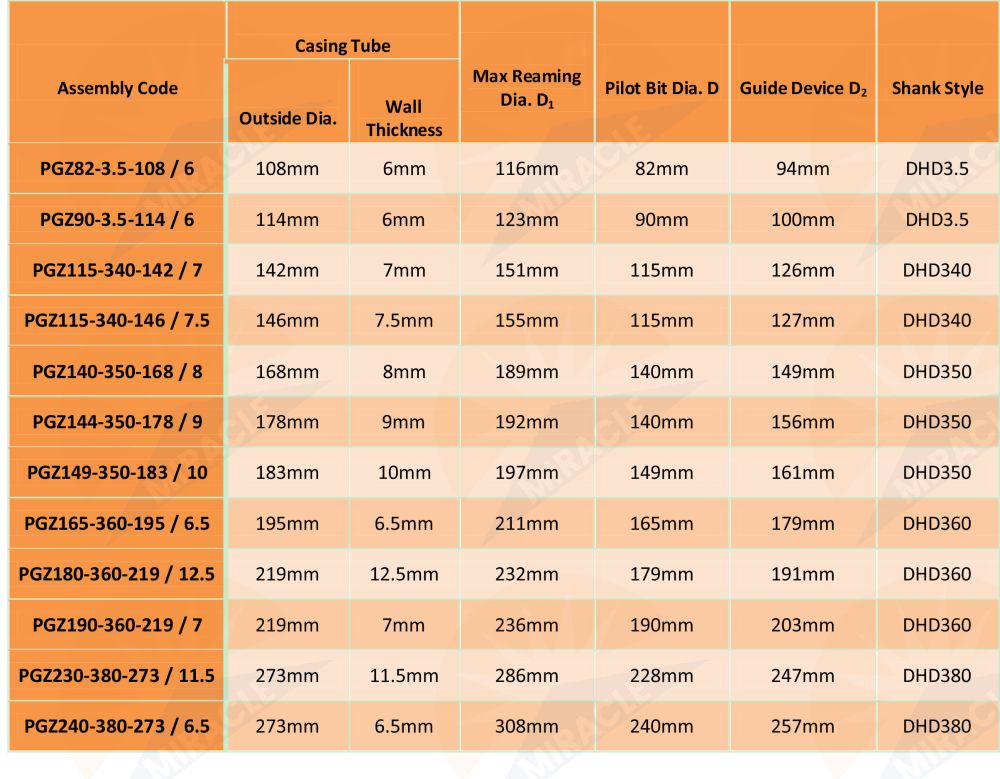

Specification:

Eccentric Casing Systems

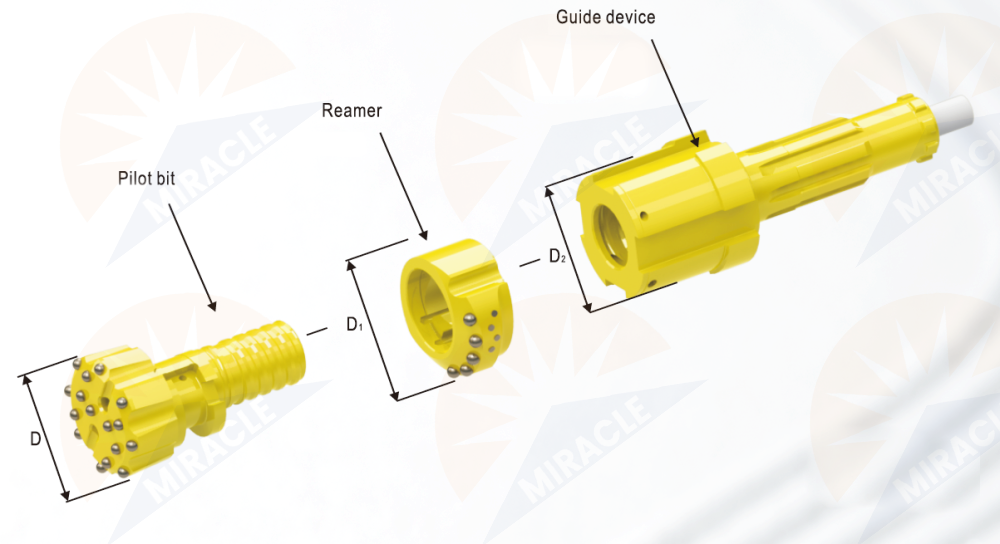

Eccentric is the most economical solution because its ingenious reaming wing the bit is retrievable can be used at the next hole.This is particularly design for shallow holes, as is often the case in water well drilling, geothermal wells, and shallow micro-piling work.The component of the Eccentric system consists of Pilot bits / Reamer bits / Guide device / and casing shoe.

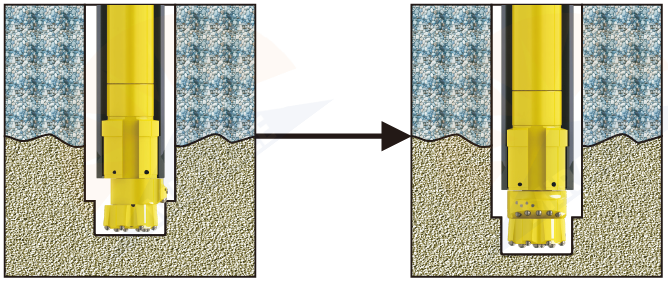

Eccentric Drilling tools with casing tube step-by-step:

1. When drilling, the TGZ reamer swings out and drills a hole wide enough for the casing tube to slide down behind the reamer.

2. When the required depth is reached, the drills are reversed, and the reamer swings in, allowing the bit to pass through the casing.

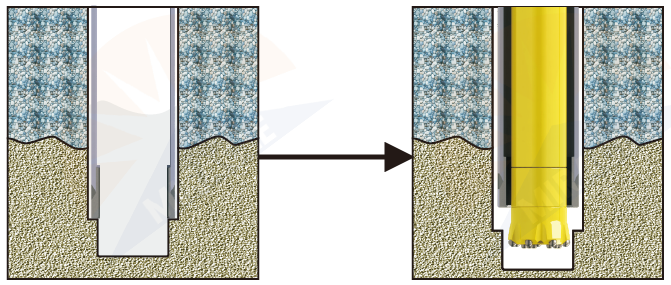

3. The casing tube is pulled out directly or fixed at the bottom of the hole by means of cement grout or other agglutinants.

4. Drilling continues to the desired depth using conventional DTH equipment.

Specification:

Product Advantages

✔ Excellent drilling speed, more flexible and efficient.

✔ Install quickly and efficiently, easy to operate.

✔ Optimal abrasion resistant, longer operating life.

✔ Stronger Pilot bit shaft for better impact energy transfer.

✔ MIRACLES Overburden Casing System can Drill in any direction & any ground.

✔ Nothing will fall down the hole unintentionally thanks to the ball bearing retaining system.

Our advantage:

1. Enterprise group combines manufacture and international trade;

2. Strict quality controll system with perfect equipment;

3. High technology enterprise with advanced production equipments;

4. Prompt delivery and all-around after-sales service;

FAQ

A: Are you trading company or manufacturer ?

Q: We are manufacturer.

A: Do you provide samples ?

Q: Yes, of course. We welcome sample order to test and check quality.

A: Can you accept small orders?

Q: We enjoy to cooperate with all clients whatever big or small order.

A: Could you accept OEM & ODM?

Q: Of course, as a manufacturer, OEM & ODM is available, our professional R&D center can help you on the project.

A: How long is your delivery time?

Q: Usually it's about 20 days,depends on your actual quantity.

Any question, pls feel free to contact . Thanks!