DTH drill bits are tools designed for rock drilling by directly sending the drill bit down the hole using a drill rod. These bits are engineered to adapt to various types of rock, offering efficient, fast, and flexible drilling characteristics.

PRODUCT INTRODUCTION

MIRACLE manufactures the finest and most efficient Down-theHole (DTH) hammers and bits for the mining, construction and water well industries. Drill and blast engineers and water well contractors trust our DTH equipment because of the precision engineering and high standards of drilling efficiency built into each of our hammers and bits.

● High-toughness carbide teeth are used, with a high wear-resistant formula (containing tantalum), so that the broken teeth rate is less than 0.2%;

● The trouser body is made of high-strength alloy steel, and after advanced heat treatment technology, the broken trouser body rate is less than 0.1%;

● Advanced CNC processing and advanced alloy tooth assembly technology are used to reduce the tooth loss rate to less than 0.1%.

PRODUCT DESIGN

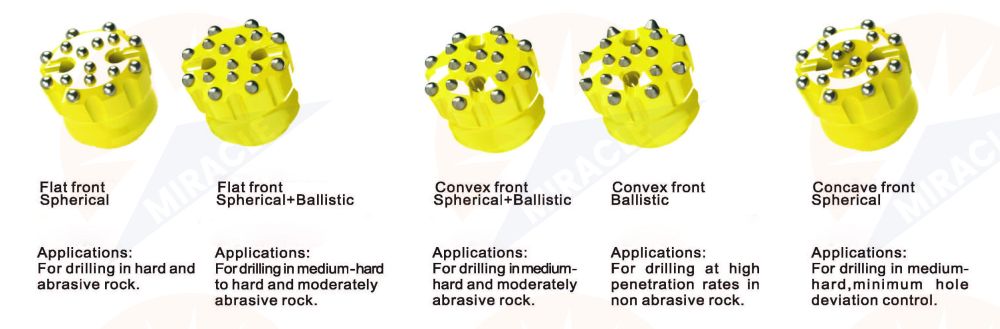

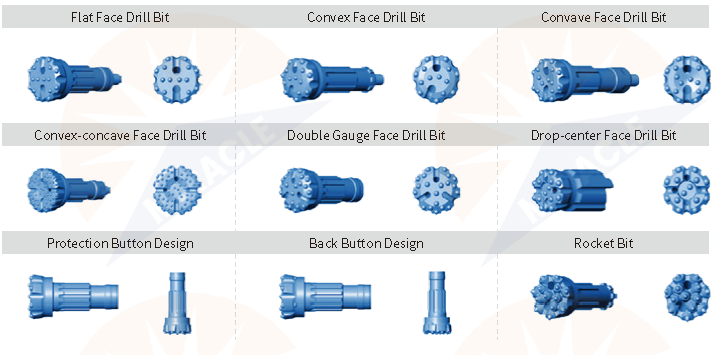

The DTH Drill Bits' heads are designed to fit specific rock formations. It often comes in four shapes:

1. Plane type: The type is appropriate for severely corrosive and hard rock formations.

2. Concave type: This type DTH Drill Bits appropriate for all types of rock formations, particularly medium-hard and homogeneous rock formations.

3. Convex type: is appropriate for soft-medium-hard layers.

4. Type of center depression: The DTH Drill Bits appropriate for cracked and soft, medium-hard, and hard rock formations.

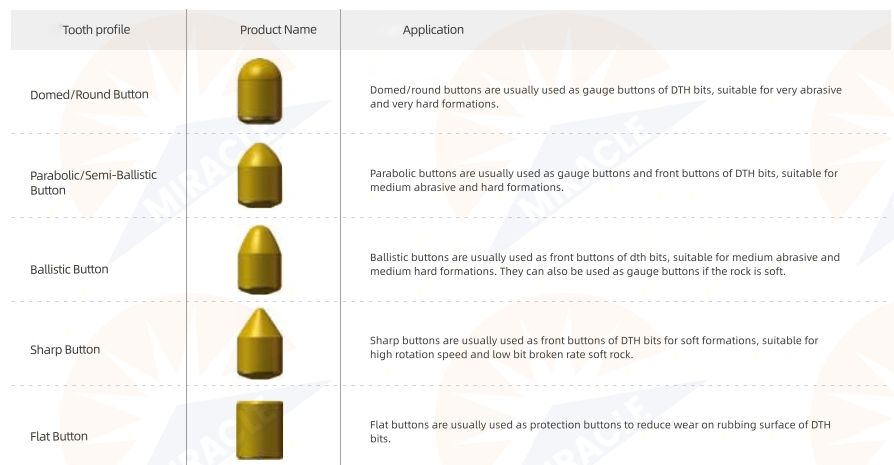

There are primarily three types of alloy teeth used in DTH Drill Bits:

carbide and face design Ball teeth, Animal thread teeth, and Spring teeth. These alloy teeth come in a variety of designs.

It is crucial to select an appropriate DTH Drill Bits shape when utilizing DTH drilling equipment since it may increase productivity and save expenses.

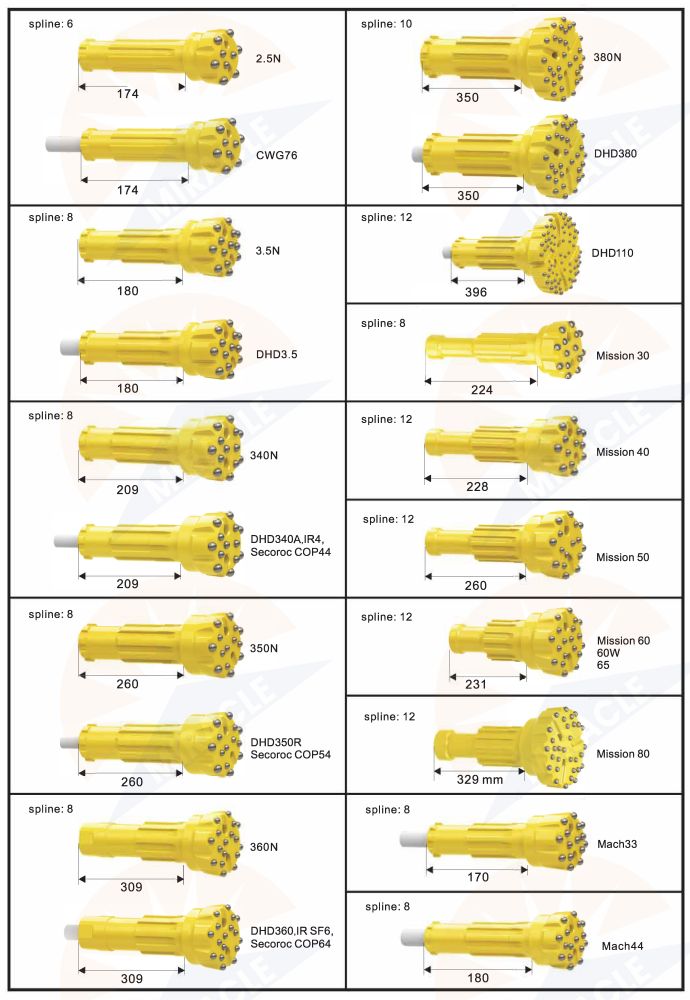

Ordering Instructions: Bit Diameter, Shank, Face form, Carbide Button Shape.

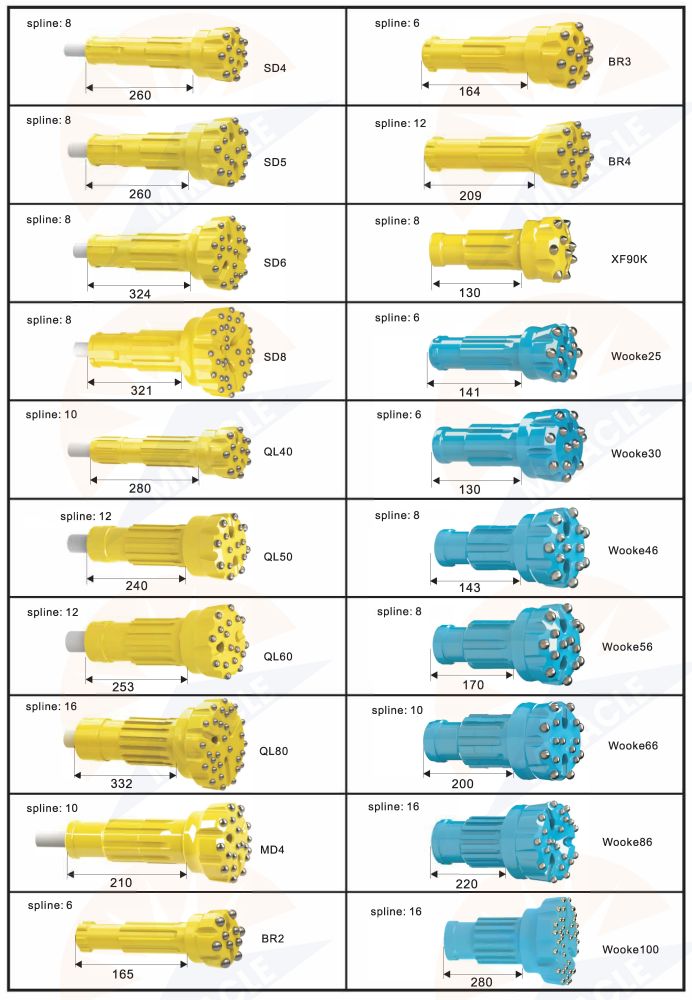

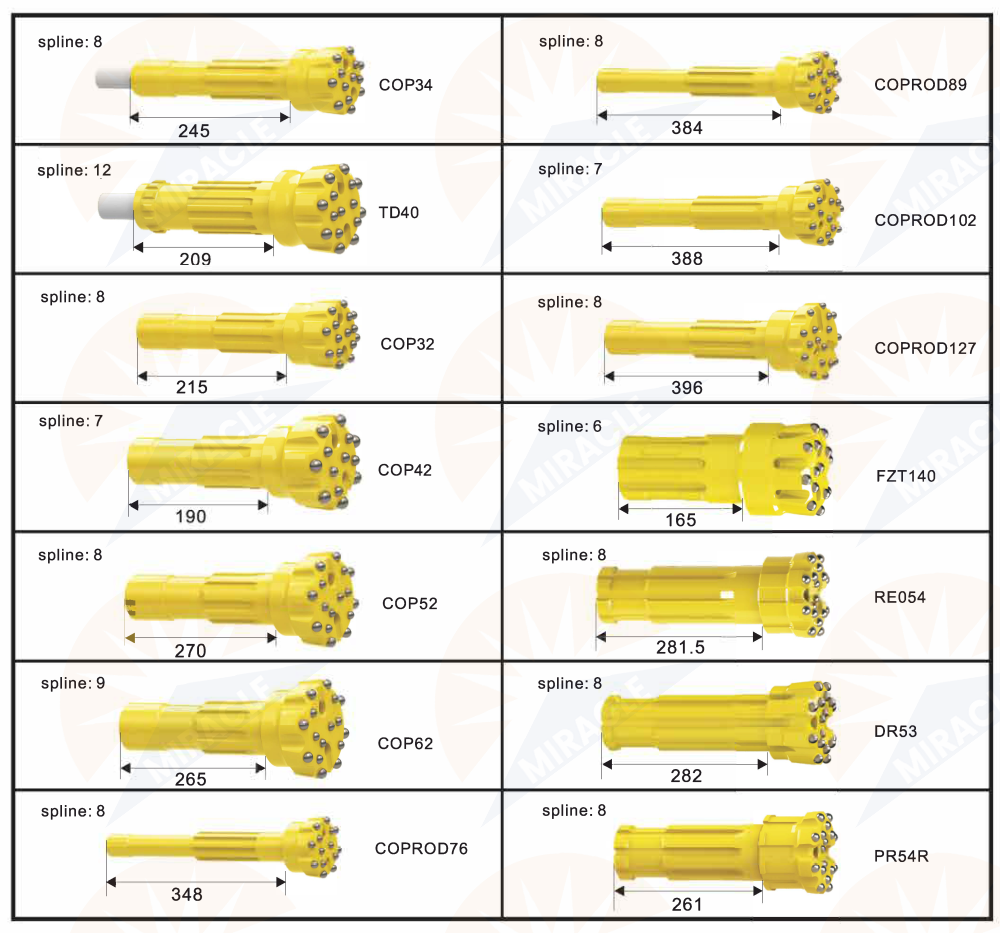

Our DTH bits have a wide variety of models of the shanks existing on the drilling markets, such as Atlas Copco’s COP32 34 44 54 64 84, Ingersoll-Rand’s DHD3.5, DHD 340A , DHD350R, DHD 360, Mission60, DHD380 QL40, QL50 , QL60, QL80, SD5, SD6, SD8, SD10, NUMA100, NUMA120 ect.

Technical Parameters:

DTH drill bits are generally divided into high air pressure series and middle-low air pressure series.

HIGH AIR PRESSURE DTH DRILL BIT:

The main features are as following:

●The longer life of the drill: the alloy material, with longer using life which better than the similar products.

●High Drilling Efficiency: the drill buttons is wear-resistant, so that the drill can always keep sharp, thus greatly improving the speed of the drilling.

●The drilling speed is stable: the bit is scraped and cut to break the rock.

●Good Performance: the New Diamond bit has strong wear resistance, good Diameter protection and can make the cutting teeth be used efficiently.

●The use of a wide range: the practice proves that the bit is suitable for carbonate rock, limestone, chalk, clav rock, siltstone, sandstone and other soft and hard (9- grade drillability of rock, hard rock drilling), compared with normal bit, especially drilling in 6-8 grade rock the effect is particularly significant.

MIDDLE-LOW AIR PRESSURE DTH DRILL BIT:

The main features are as following:

● The single impact energy is large, and the energy consumption of rock crushing is low;

● Fast drilling speed, high rock breaking efficiency, wear resistance and impact resistance, low labor intensity for workers.

● The central exhaust and slag removal effect is good, which reduces the repeated crushing of rocks.

● Straight drilling, fast speed and deep drilling.

Bit Shank Identification Chart:

Packing

Using ply-wooden cases and pallet for package to protect the products and avoid the damaging during transportation. Also we can customize package according to your special requests.

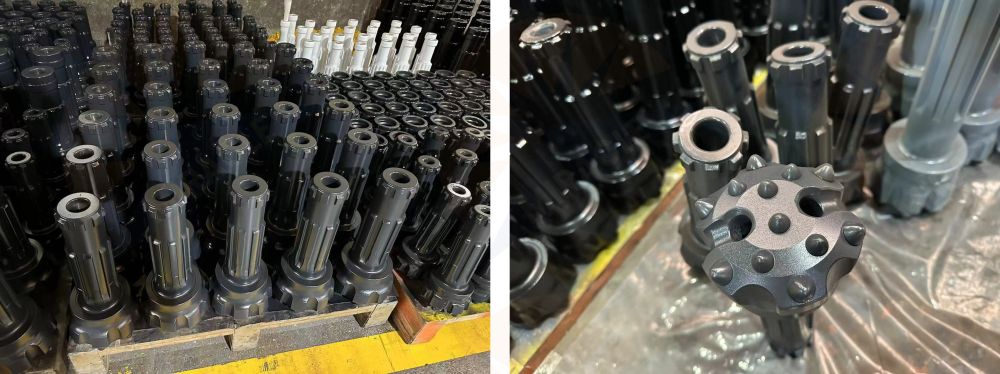

Finished product preview

We're well-known as one of the leading dth drill bits manufacturers and suppliers in China. Please feel free to buy high quality dth drill bits at competitive price from our factory. Good service and punctual delivery are available.

Our advantage:

1. Enterprise group combines manufacture and international trade;

2. Strict quality controll system with perfect equipment;

3. High technology enterprise with advanced production equipments;

4. Prompt delivery and all-around after-sales service;

FAQ

A: Are you trading company or manufacturer ?

Q: We are manufacturer.

A: Do you provide samples ?

Q: Yes, of course. We welcome sample order to test and check quality.

A: Can you accept small orders?

Q: We enjoy to cooperate with all clients whatever big or small order.

A: Could you accept OEM & ODM?

Q: Of course, as a manufacturer, OEM & ODM is available, our professional R&D center can help you on the project.

A: How long is your delivery time?

Q: Usually it's about 20 days,depends on your actual quantity.

Any question, pls feel free to contact . Thanks!