Diamond composite ( PDC) is a special superhard material synthesized from artificial diamond and cemented carbide at one time under high temperature conditions.

It not only has the advantages of high hardness and wear resistance of diamond, but also has the characteristics of strong impact resistance and large blade of cemented carbide. Using it as the blade of the drill bit can greatly improve the working efficiency of the drill bit. It is an ideal drill bit for drilling medium-hard rock and hard rock formations.

PDC drill bits are suit for soft to medium hard rock layers below grade 7, and have two manufacturing processes: matrix type and steel type.

Strength distinction:

The strength of diamond composite drill bits is mainly determined by the strength of the diamond composite sheet. At present, diamond composite drill bits are mainly divided into three types in terms of strength: ordinary type, reinforced type, and high strength type; diamond composite sheets are mainly divided into two types: 1304 and 1308. 1304 and 1308 refer to the diameter and thickness of the composite sheet. The basic distinction we use is: ordinary type, reinforced type, and high strength type; among them, the ordinary type is 1304 flat composite sheet, the reinforced type is 1304 spherical composite sheet and 1308 flat composite sheet, and the high strength type is 1308 spherical composite sheet.

The blade of the high strength diamond drill bit adopts the newly developed ball-shaped diamond blade, which is characterized by fast drilling speed and strong impact resistance. When the drill bit is drilling, the lip is used to scrape the normal uniform formation rock, and the protruding part of the drill bit can instantly make a large amount of penetration when encountering a gap during the drilling process, which greatly reduces the accidental damage of the drill bit and improves the drilling level for complex rock formations. The parameters of the applicable rock formation and drilling procedures are shown in the table below:

Adaptive rock formation parameter table:

| Type | Adapt to rock formation |

|---|---|

| Ordinary PDC drill bit | Soft to medium hard rock with F <10 |

| Strengthen PDC drill bit | Medium hard rock with F=10-12 |

| High strength PDC drill bits | Hard rock with F <18 |

Diamond composite ( PDC) drill bit drilling procedure recommended parameter table:

| Specifications (mm) | Drilling procedure parameters | ||

| Drilling pressure (Kg) | Speed (rpm) | Pump capacity (1/min) | |

| F28 | 300-700 | 300-350 | 150-200 |

| F30 | 300-700 | 300-350 | 150-200 |

| F32 | 300-700 | 300-350 | 150-200 |

| F48 | 300-700 | 300-350 | 120-160 |

| F56 | 320-800 | 250-350 | 130-180 |

Φ75 | 480-1200 | 200-300 | 150-200 |

| F94 | 640-1600 | 150-250 | 200-250 |

Φ110 | 880-2200 | 120-200 | 200-300 |

| F152 | 1500-3000 | 100-200 | 500-850 |

Φ190 | 1800-4000 | 100-200 | 600-1200 |

Φ230 | 2200-4500 | 100-200 | 750-1400 |

Φ270 | 2400-5000 | 100-200 | 1000-1500 |

Application Field :

At present, the application field of diamond composite drill bits is relatively broad. Our company's diamond drill bits are used in coal fields, oil drilling, geological exploration, water conservancy and hydropower, railways and highways, tunnel construction and other industries across all over the world.

The two-wing PDC anchor drill bit (half-piece standard type) is suitable for rock formations below level 8. Under the same rock formation conditions, the drilling life is 10-30 times that of ordinary alloy drill bits. The efficiency is improved and no grinding is required, which greatly reduces the labor intensity of workers and saves working hours. The key raw materials of the blade of the two-wing PDC anchor drill bit (half-piece reinforced type) are produced by GE of the United States. Its diamond content is 1.5 times that of ordinary drill bits, with significantly improved wear resistance and efficiency, and reduced comprehensive costs. It is suitable for medium-hard rock formations below level 12.

Product Advantage:

Our Diamond Composite Drill Bits have a support body made of forged steel and are treated with vacuum fully automatic heat treatment equipment to increase mechanical properties. The common type uses domestic composite pieces as blades, and the High Strength type uses blades produced by GE of the United States. The corresponding quality grade is selected according to different geological conditions, which can achieve a higher product cost performance and achieve the economic index of energy saving.

The two-wing PDC anchor drill bit (half-piece standard type) is suitable for rock formations below level 8. Under the same rock formation conditions, the drilling life is 10-30 times that of ordinary alloy drill bits. The efficiency is improved and no grinding is required, which greatly reduces the labor intensity of workers and saves working hours.

The key raw materials of the blade of the two-wing PDC anchor drill bit (half-piece reinforced type) are produced by GE of the United States. Its diamond content is 1.5 times that of ordinary drill bits, with significantly improved wear resistance and efficiency, and reduced comprehensive costs. It is suitable for medium-hard rock formations below level 12.

We manufacture various types of PDC coring bits, and customers can choose from 3 wings to 7 wings and from diameter 3 1/2” to 12 1/2”. But the PDC bits used for petroleum exploration require higher quality for the PDC, it must be confirmed when they order.

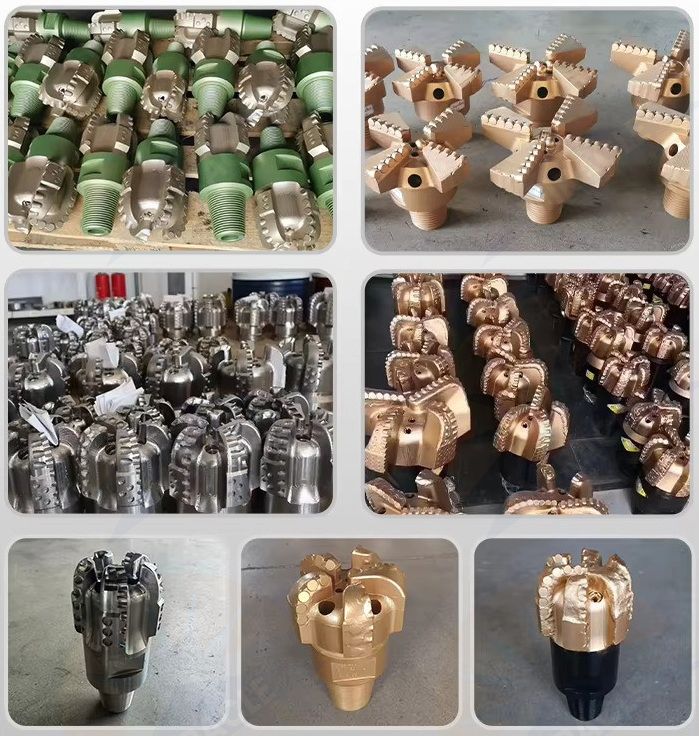

Product Display:

Our advantage:

1. Enterprise group combines manufacture and international trade;

2. Strict quality controll system with perfect equipment;

3. High technology enterprise with advanced production equipments;

4. Prompt delivery and all-around after-sales service;

FAQ

A: Are you trading company or manufacturer ?

Q: We are manufacturer.

A: Do you provide samples ?

Q: Yes, of course. We welcome sample order to test and check quality.

A: Can you accept small orders?

Q: We enjoy to cooperate with all clients whatever big or small order.

A: Could you accept OEM & ODM?

Q: Of course, as a manufacturer, OEM & ODM is available, our professional R&D center can help you on the project.

A: How long is your delivery time?

Q: Usually it's about 20 days,depends on your actual quantity.

Any question, pls feel free to contact . Thanks!