Impregnated diamond core bits are the most commonly useful bits in the mineral exploration industry, as they have the widest range of application. The carefully selected grades of high quality synthetic diamond are distributed in the depth of impregnated bit's matrix series. The matrix layer contains a uniform distribution of these crystal that are embedded in a powdered metal bond.

We possess professional ability of WL/ Q series drill bits and reaming shells. Our drilling bits have first-class quality , excellent performance. Bits and reaming shells are designed on basis of ground condition. In respect of drilling in speed and useful life,our products are the most competitive products in China.

Shapes of lips: flat-bottom,circular,serration,pointed teeth,angle teeth,ladder,and ladder with end spray .

Standard: To cooperate with Q series drilling tools,bits are designed on basis of different stratum condition. Ourcompany also design and produce non-standard drilling bits according to customer's special requirements.

Recommendation: When hardness of stratum is high,low grade drilling bits are recommended to ensure matching of stratum.

Size:BWL, NWL, HWL, PWL etc.Also, non-standard sized bits can be produced according to requirements from clients.

Crown Height:

we offers crown depths of 10mm, 12mm, 14mm.The taller crown heights provide improved bit stability and reduced vibrations, enhancing bit life and performance. Unless otherwise specified, a standard 14mm impregnation depth is supplied for most of our customer.

Waterways:

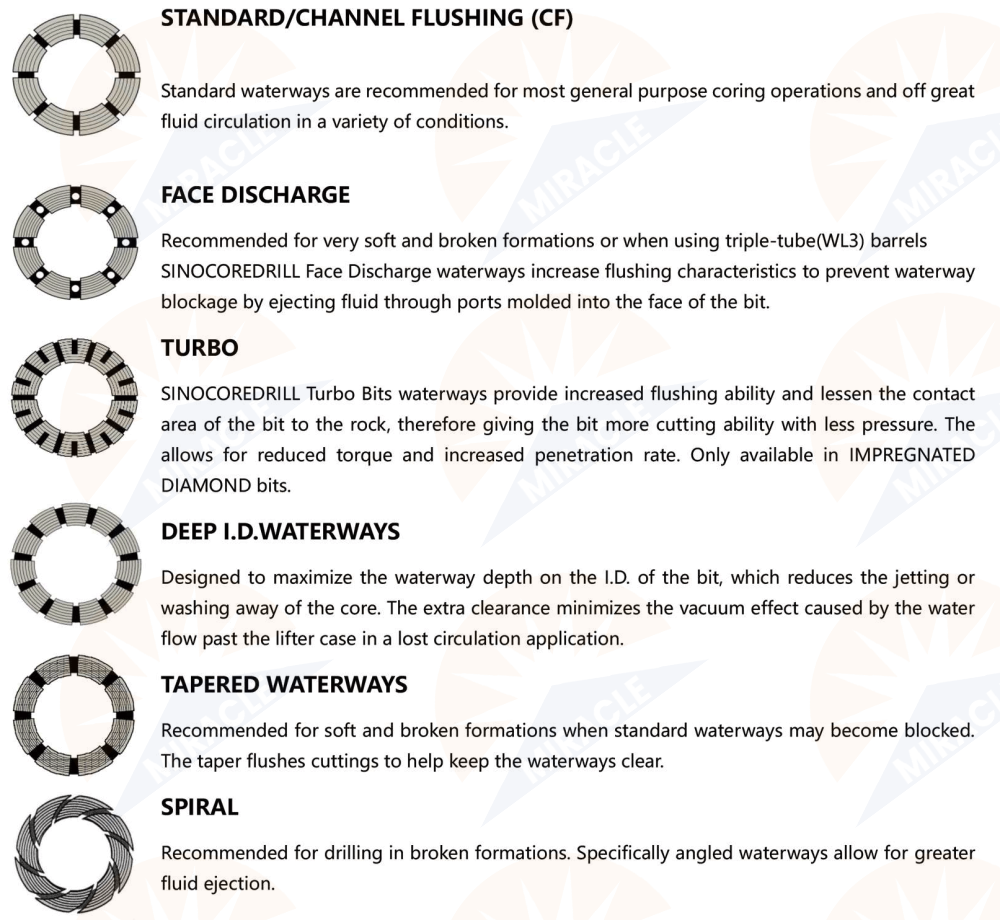

Various waterways are available for diamond impregnated bits.Differing waterways allow for better flushing in various ground conditions and drilling systems.

Matrix hardness:

For convenience of customer from different countries, Sinocoredrill impregnated bit matrices adopts the international standard matrix number system. Matrices to be used on various rock conditions can be ordered according to the MATRIX SELECTION CHART.

Threads:

Standard DCDMA threads as well as thread types required by clients are available.

Specifcation of Diamond core bits

Main features:

1. Greater resistance to wear in most formations, particularly in the extremely hard rock formation.

2. Less sensitive to abuse, rough handling and improper use.

3. Self sharpening owing to the erosion of matrix and the diamonds.

4. Synthetic diamonds of high quality which are distributed evenly throughout the matrix.

5. Efficient cutting function provided by fresh, sharp diamonds continually.

Size Available:

Wireline series: WLA, WLB, WLN, WLH, WLP, WLB3, WLN3, WLH3, WLP3, WLN2, AQ, BQ, NQ, HQ, PQ, SQ, PQ3, HQ3, NQ3, BQ3, NQ2, WL-56, WL-66, WL-76

T2 / T series: T2 46, T2 56, T2 66, T2 76, T2 86, T2 101, T46, T56, T66, T76, T86

TT series: TT 46, TT 56

T6 series: T6 76, T6 86, T6 101, T6 116, T6 131, T6 146

T6S series: T6S 76, T6S 86, T6S 101, T6S 116, T6S 131, T6S 146

B series: B46, B56, B66, B76, B86, B101, B116, B131, B146

MLC series: NMLC, HMLC

LTK series: LTK48, LTK60

WF series: HWF, PWF, SWF, UWF, ZWF

WT series: RWT, EWT, AWT, BWT, NWT, HWT(Single Tube, Double Tube)

WG series: EWG, AWG, BWG, NWG, HWG(Single Tube, Double Tube)

WM series: EWM, AWM, BWM, NWM, HWM

Other sizes: AX, BX, NX, HX, TBW, NQTT, HQTT, TNW, 412F, BTW, TBW, NTW, HTW, T6H

Chinese standard: 56mm, 59mm, 75mm, 89mm, 91mm, 108mm, 110mm, 127mm, 131mm, 150mm, 170mm, 219mm, 275mm

Russian standard: 59, 76, 93, 112, 132, 152 mm

How to select the diamond core bits?

How to select the diamond core bits?

When selecting a bit there are 3 main factors that contribute to decision making.

○ Rock Hardness

Measured using MOHS hardness scale: The Mohs scale of mineral hardness is a qualitative ordinal scale that characterizes the scratch resistance of various minerals through the ability of a harder material to scratch a softer material.

○ Rock Formations

Rock types are classified by their different chemistry and structure. Hardness in theory is relative; therefore, soft rocks can prove more difficult to drill than hard rock. Also, the same rock formations, in different locations, can drill differently.

Factors that Determine Drillability

① Grain Size

② Rock Hardness

③ Weathering and Fracturing

○ Bit Characteristics

Matrix – Each of the matrices has a different rate of wear. The matrix chosen is ideal when there is a balance between the wear of the matrix material and the diamonds exposing ensuring a high rate of penetration and optimum bit life.

Gauge – The outer (hole) and inner (core) dimensions of the bit.

Crown Height – Ranging from 4mm to 14mm in height. With higher crowns available upon request. The height of the crown is chosen based of hole depth and wear rate.

Waterways – There are multiple different waterway configurations depending on the drilling conditions.

How to select AQ, BQ, NQ, HQ, PQ?

AQ Diamond Core Bit:

AQ diamond core bits are high-performance tools specifically designed for mineral exploration. It has superior diamond cutting technology.

BQ Diamond Core Bit:

The BQ impregnated diamond core bit is a high-quality drilling tool designed for demanding geological and geotechnical exploration projects. It features a robust design,and equipped with a high concentration of industrial-grade diamonds.

HQ Diamond Core Bit:

HQ diamond core bits designed to meet the highest standards of quality and performance in the drilling industry. It is Constructed with a high concentration of industrial-grade diamonds embedded in a high-strength matrix, capable of cutting through even the toughest materials with ease.

NQ Diamond Core Bit:

NQ diamond core drill bits are a must-have tool for any contractor or DIY enthusiast who needs to drill through tough materials such as concrete, brick, stone, or asphalt. Its main feature is its high-quality diamond coating, which is applied using advanced technology to ensure that it adheres firmly to the drill bit and remains sharp even after prolonged use.

PQ Diamond Core Bit:

The PQ Imp core bit is a high-quality diamond drilling accessory designed to provide superior performance in challenging drilling environments. Its main feature is its diamond impregnated segments., which are strategically placed on the cutting surface to provide maximum contact with the rock formation, resulting in faster and more efficient drilling.

Our advantage:

1. Enterprise group combines manufacture and international trade;

2. Strict quality controll system with perfect equipment;

3. High technology enterprise with advanced production equipments;

4. Prompt delivery and all-around after-sales service;

FAQ

A: Are you trading company or manufacturer ?

Q: We are manufacturer.

A: Do you provide samples ?

Q: Yes, of course. We welcome sample order to test and check quality.

A: Can you accept small orders?

Q: We enjoy to cooperate with all clients whatever big or small order.

A: Could you accept OEM & ODM?

Q: Of course, as a manufacturer, OEM & ODM is available, our professional R&D center can help you on the project.

A: How long is your delivery time?

Q: Usually it's about 20 days,depends on your actual quantity.

Any question, pls feel free to contact . Thanks!